Understanding Boat Engine & Motor Terminology

STEP #2 UNDERSTANDING THE TERMINOLOGY FOR YOU BOAT REPOWER PROJECT

After getting a handle on the EPA guidelines for repowering as we covered in STEP #1, the next thing is to get make sure you fully understand the terminology that’s used to describe the different marine propulsion products and options. The listing below is not all inclusive but does detail the the most commonly used terms used when determining how to power your boat. It’s extremely important to understand the difference between a longblock vs a short block engine, what is considered as standard rotation for a marine engine, what is a bobtail engine, etc. Fully understanding these terms and descriptions will put you in a better position when you start talking with the suppliers, and buy a replacement boat engine or the parts and accessories that will be needed to complete your boat repower project. (Select blue hyperlinks below to read more detail with each topic)

Engine Rotation….(Read More) – No matter whether you choose a longblock, power-package or complete turnkey bobtail engine the rotation of the motor is a critical item to know. Rotation with marine engines is always viewed from behind the engine looking towards the engine flywheel. Within the Marine Industry “Standard Rotation” (left hand) means the flywheel is turning counter clockwise looking at it from the rear of the engine, or another way to think of it is that the harmonic balancer will turn clockwise when standing in front of the engine to view it. “Opposite Rotation” engines (right hand) were common years ago however they have not been regularly produced today because the newer models of transmissions (Hurth & Velvet Drive) both have negated the need for this since the transmissions can rotate either direction without issue.

Marine Engine Longblock….(Read More) – This is a great value based option for boaters with freeze damaged motors, or in the event that you experience any general engine failure but are not in the position to buy a completely dressed out turnkey bobtail engine. The term “Longblock” generally refers to the cylinder block & heads as well as the required internals of the engine which are called the rotating assembly of the engine. Longblocks being classified as non-complete engines are therefore not currently regulated by the EPA as the new complete turnkey bobtail engines are. Marine Longblocks are therefore NOT forced to come equipped with a Marine Catalyst System.

Generally these marine longblocks do not include the intake manifold, engine circulating pump, or flywheel however this does vary when comparing new vs remanufactured longblocks. Depending on the brand of the longblock product and whether it’s a new or remanufactured longblock it may be supplied with the “Tin Ware” (oil pan, valve covers, timing chain cover) as well as some of these additional accessory items. Unless it is specified up front the remanufactured longblocks are almost never supplied with the “Tin Ware”, however new longblocks are normally supplied with the “Tin Ware” as well as the flywheel and harmonic balancer. The reasoning behind this variation in the content that is supplied with the longblocks comes down to cost control. The flywheel, balancer and tin ware are not considered to be items that normally wear out and need to be replaced. Therefore, the remanufactured longblock manufacturers do not include these items.

NOTE: Please be aware that Marine “Shortblocks” are no longer available. The primary reason behind this was that the cost difference between a longblock versus a shortblock was insignificant versus the significantly higher number of warranty issues that resulted with shortblocks. The two primary reasons for the higher number of warranty issues was driven by the fact that the shortblocks cannot be fully tested after manufacturing like the longblocks can. The other reason was that when existing cylinder heads that have valve seating issues were installed onto a new shortblock it almost always causes serious longevity issues to the engine which is out of the direct control of the manufacturer.

IMPORTANT: When repowering your boat by replacing the longblock it should be noted that none of the manufacturers will cover warranty for ANY water ingestion related failures. Therefore, if you are replacing a longblock due to freeze damage you need to either be 100% sure your exhaust system (Read More…) is not cracked, or it is simply recommended to just replace the exhaust to be safe. We also recommend replacing your engine coupler (Read More…) whenever replacing the longblock. The coupler is an item with a specified life span since it transfers the power from the engine to the sterndrive or transmission. The coupler is much like a clutch in a manual transmission automotive application and it can only be replaced while the engine is out of the boat.

Power Package….(Read More) – These products are also referred to as Par-Pac’s which is short for “Partial Package”. These terms all refer to the growing market for partially completed engines. These range from new longblocks with the marine fuel and electrical systems already installed, but due to the EPA Guidelines they do not include the exhauust systems as that would require them to be supplied with Catalyst Systems. Just like the New Longblock products detailed above, Power Package’s are classified as a non-complete engines and therefore they are not regulated by the EPA like the New Completely Dressed Bobtail Engines. Therefore, the Power Packages are NOT forced to come supplied with a catalyst system. The main selling point of the Power Packages is that they work great for the customer needing a replacement engine product, but most of their ancillary accessories are still in good shape and don’t need to be replaced.

Two other great applications for the Marine Power Package are when you are replacing a 5.0L and want to the larger displacement and performance of the 5.7L engine, or when you are replacing an older pre-1996 260 Hp 5.7L and want the additional performance offered by the 300 Hp Vortec 5.7L engine model.

Bobtail Marine Engine….(Read More) – This term generally refers to a new or remanufactured, completely dressed “turnkey” engine. NEW Bobtail Engines require more hurdles to jump over due to the EPA Repowering Guidelines as outlined in STEP #1 of the Boat Repowering Guide. Depending on the manufacturer of the product in question these “Bobtail” products generally come complete with fuel, electrical, cooling, and exhaust systems as well as the engine mounts and bell housing which makes “Bobtail Engines” ready to drop right in when replacing completely “worn out” engines. Turnkey bobtail engines are classified as complete engines so as of 2010, NEW Bobtail Engines are in fact regulated by the EPA and now forced to be supplied with a catalyst system (Read More).

In an effort to combat the introduction of the EPA regulations in 2010 MerCruiser introduced their PLUS Series (Read More) and CPO product lines (Read More) for Bobtail Marine Engines, Sterndrives and outboard motors. All of these product lines have proven to be be extremely successful since their introduction. For the obvious benefit of working around the EPA issue that requires the catalyst system and controls, the CPO and PLUS Series product lines now makes up the vast majority of repowers that require a completely dressed motor to be used. When the condition of the existing engine in your boat you are replacing dictates that a complete bobtail engine is required, you will first need to determine if the existing engine drive coupler can be used, and then if the existing sterndrive or transmission will couple directly to this. In many cases, if the engine you are replacing is more than 15 years old you will likely have to change out the main engine electrical harness connection plug because these have changed over the years. It is also common on these 15+ year old engines for the exhaust system to have changed since the exhaust systems went changed from 3 inch to 4 inch outlet designs to accommodate the increasing levels of engine output.

Complete Package – This term refers to the combination of a New, Completely Dressed Bobtail Engine, and in the case of a Sterndrive Package it would include the Transom Assembly/Shield (sometimes also referred to as the Gimbal Assembly) along with the Sterndrive. For Inboard Packages it would include a New Engine and the Transmission. Select this link to read more about Sterndrives versus Inboards.

“Complete Packages” is a term that is normally reserved only for NEW products, and NOT the CPO or PLUS Series lines of remanufactured marine products. You could put together a “Complete Package” using either the CPO or PLUS Series products or a combination of remanufactured and new, however you would have to separately purchase the trim pump, exhaust Y Pipe and a few other additional accessory items to match the same level of content that is/was supplied with the “New Complete Packages”.

NOTE: Most manufacturers do not sell Complete Packages today rather they sell everything a la carte between the engine, sterndrive, transom assembly and/or transmission. You still end up with an all New Complete Package in the end, however unlike it was in the past you have to piece the package together item by item by selecting the specific engine + sterndrive + transom assembly.

Sterndrive….(Read More) – This term refers to the drive or propulsion system on Inboard/Outboard powered boats. Therefore, this labels teh drive system itself which incorporates an engine inside of the boat, along to a drive unit that mounts onto the transom and is located outside of the boat. The different sterndrive designs used to power these “Inboard/Outboard” boats can utilize either single or dual propeller drive designs. Two manufacturers; MerCruiser & Volvo Penta make up roughly 99% of all the OEM sterndrive sales worldwide.

Transom Assembly….(Read More) – Also referred to as the gimbal assembly or transom shield in the case of Volvo Penta products this term refers to the connection point between the engine and sterndrive on Inboard/Outboard powered boats. The transom assembly includes both a plate that mounts on the inside of the boat and incorporates the rear engine mounts. The transom assembly also includes the exterior portion you see visibly on the outside of the boat. The transom assembly contains the sterndrive bell-housing and is what allows the range of motion necessary for the drive to not only steer from left to right but also the upward and downward articulation. Since the transom assembly is teh connection point of the engine and sterndrive it is also what the main alignment point between the engine and drive by way of the “Gimbal Bearing” Checkout the following article and video regarding proper drive/coupler alignment….(Read More).

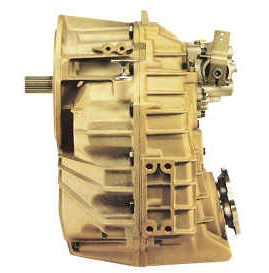

Transmission – Also referred to as the gearbox, this is the drive system on inboard powered boats. These typically come in different gear ratios and also different output flange angle configurations as required by specific prop shaft angles. These output flange variations include inline, down angle and V-drive configurations.

Select this link to read more about Inboard Drive Variations.

Helpful Hint – Be aware that most early twin engine powered inboard boat models used the cast-iron-body version of the Borg Warner Velvet Drive transmissions. These transmissions were then used in combination with 1 standard rotation engine and 1 opposite rotating engine. With the early version Twin Engine powered boats there were very few options available for the propshaft angle. Therefore the engine had to be installed such that the crankshaft was also at the required prop shaft angle. In the early 1990’s the bi-directional ZF Hurth and Velvet Drive 5000 series aluminum body transmissions were introduced which very quickly negated the need for opposite rotating engines. Therefore if you are looking to repower an older boat that includes the above described engine & transmission setup with a completely dressed bobtail engine, this creates an issue due to the fact that the newer style transmissions do not share the same mounting configuration but the newer engines do not offer an opposite rotation model. Therefore, you get stuck having to rework the stringers in the boat to accept the newer style transmission mounts and position.

RETURN TO BOAT REPOWER GUIDE MAIN PAGE