Marine Exhaust | Gaskets | Torques | Coatings | How-To Tips

Marine Exhaust Manifolds and Technical Tips.

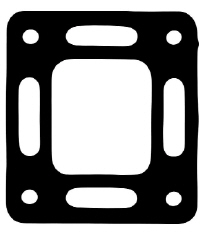

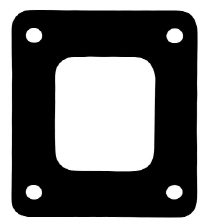

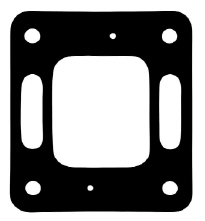

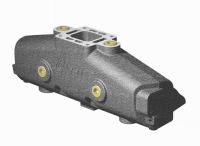

CLICK HERE TO SHOP ONLINE When the time comes to replace your manifolds, the easiest way to insure getting the proper parts for the job is to take a look at your current exhaust system and write down the casting numbers which are on each part. In some cases the casting number is on the engine side of the manifold and may be hard to see prior to removal. Some exhaust manifolds may have no number at all, making it difficult, but not impossible to identify. This is where engine model number information is helpful. Try and find your engine manufacturer and then match up to the model number information to that. In many instances your motor may be several years older than the boat. The installer, whether a hired mechanic or the boat owner, must be aware of the importance of proper gasket installation at the riser to manifold surface. Water leakage at this point is virtually always a gasket seal problem, not a defective part (however, water leakage at an improperly installed gasket will eventually damage the iron parts in addition to allowing water into the engine). Please read our tech tips for installation of gaskets further down the page. Understanding the plumbing of a manifold may help in the installation and reassembly of your manifolds and risers. Familiarize yourself with the OEM service manual and make sketches or photographs of your plumbing system prior to disassembly. This may avoid problems with the installation. Remember to drain water from your manifolds and risers prior to removal of any of the pieces. Failure to drain the parts can result in damage to your engine due to water ingestion. Do not alter or modify gaskets. Order the correct marine exhaust products for your specific boat application. WHEN SHOULD YOU REPLACE MARINE EXHAUST MANIFOLDS AND RISERS? ARE THE OEM EXHAUST PRODUCTS BETTER THAN AFTERMARKET? PAINT & COATINGS (Read More): EXHAUST GASKETS: BOLTS & TORQUE: Studs: To prevent studs from backing out and causing leaks which can cause engine damage, use red thread locking compound. Follow the manufacturers recommendations for their installation and removal. Do not use anti-sieze on bolts or studs as it is a lubricant and will cause fastener to back out. PIPE PLUGS AND FITTINGS: GASKET PLACEMENT: In some applications the riser gasket alignment is critical. Improper installation of the gasket can cause the engine to have an overheating concern. The following is a list of these gaskets and how they should be aligned:

NOTE: For Dry Joint Exhaust Gaskets please read this separate technical article (Read More)

Marine Exhaust – KEEL COOLING: Keel Cooling is often installed incorrectly and can cause manifolds to crack internally from excessive heat. Do not install exhaust manifolds into keel cooled systems that rely solely on the water circulation pumps with a small diameter pipe for its circulation. This is not satisfactory and will overheat the exhaust manifolds. |